-

Hydraulic Breaker Hammers

-

Hydraulic Excavator Hammers

-

Hydraulic Demolition Hammer

-

Hydraulic Breaker Chisels

-

Hydraulic Rock Breaker

-

Hydraulic Breaker Drill Rod

-

Hydraulic Jack Hammer

-

Excavator Breaker Attachment

-

Hydraulic Pulverizer

-

Excavator Plate Compactor

-

Excavator Quick Hitches

-

Hydraulic Excavator Breaker

-

DavidNice hammer from Hanyun, their service great, I love their price more

DavidNice hammer from Hanyun, their service great, I love their price more -

MarkHydraulic breakers from HY suit my CAT well, it beats the ground powerfully, the sound beautiful.

MarkHydraulic breakers from HY suit my CAT well, it beats the ground powerfully, the sound beautiful.

| Item 1 | Chisel For Hydraulic Hammer | Item 2 | Chisel For Hydraulic Breaker |

|---|---|---|---|

| Breaker Chisel Diameter | 180mm | Customized Length | Available |

| Type | Hydraulic Breaker Tools | Applicable Vehicle Weight | 40T |

| Nearest Port | Qingdao Port, Tianjin Port, Shanghai Port | Chisel Head | Forge Steel Head |

| Highlight | 180mm Hydraulic Breaker Chisels,40T excavator Hydraulic Breaker Chisels,VOLVO demolition hammer chisel bits |

||

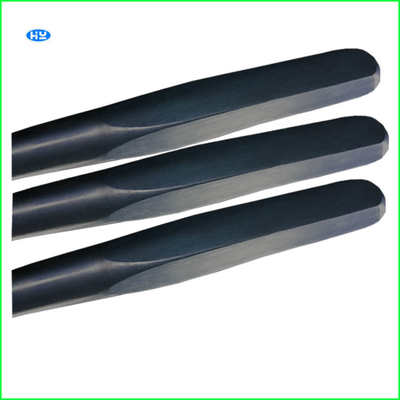

180mm Chisel For Hydraulic Breaker Chisel For Hydraulic Hammer

(1) Main technical parameters on 180mm chisel for hydraulic hammer

Model: HYQG180

Breaker chisels diameter: 180mm

Hydraulic hammer tools length: 1700mm or customized length

Breaker chisel weight: 280kgs

Applicable carrier weight: 40t

Applicable excavator brand: SANY, XCMG, LIUGONG, SHANTUI, CAT, HYUNDAI, DOOSAN DAEWOO,

VOLVO, KOMATSU, KOBLECO, KUBOTA, HITACHI, XGMA, FOTON, STRONG

ZOOMLION

(2) Details of Applicable Hydraulic Hammer HY180

Model: HY180

Keywords: hydraulic breaker hammer/hydraulic rock hammer

Driving oil pressure:280-300KG/CM2

Drivign oil flow:220-270L/MIN

Striking frequency:180-220BPM

High pressure soft hose diameter: 1.2 inch

Overall size: 2240*750*1620mm

Weight: about 4950kgs

(3) How to manufacture one hydraulic breaker chisel?

To fabricate one good quality excavator hydraulic breaker chisel, below steps are needed:

1. Good quality raw materials---round steel purchasing;

2. Saw and cut the round steel to different length according to different demands;

3. Process the cutted round steel, to make the outline as a drill rod;

4. Process the flat pin groove with milling machine;

5. Polish the drill rod;

6. Heat treatment on the breaker chisels drill rods;

7. Do shotblasting treatment on the appearance, making it smooth;

8. Nitrate tempering treatment;

9. Painting on the drill rod

![]()

(4) How to pack and ship the chisel for hydraulic hammer?

Packing: firstly packed with thick paper, then packed with exported plywood pallets;

Shipping: load the packed chisels into container, then shipped by sea or by road

![]()